Ukugqwala ukulimala noma ukuwohloka kwezinto noma izakhiwo zazo okubangelwa isenzo sendawo ezungezile.Ukugqwala okuningi kwenzeka endaweni esemoyeni, equkethe izingxenye ezigqwalile kanye nezici ezigqwalayo ezifana nomoya-mpilo, umswakama, ukushintsha kwezinga lokushisa kanye nokungcola.

Ukugqwala kwesifutho sikasawoti kuyindlela evamile futhi eyingozi kakhulu yokugqwala komkhathi.Ukugqwala kwesifutho sikasawoti ebusweni bezinto zensimbi kubangelwa ama-ion e-chloride aqukethwe endaweni yensimbi engena ngongqimba lwe-oxidation kanye nongqimba oluvikelayo kanye nokusabela kwensimbi ye-electrochemical yangaphakathi.Ngesikhathi esifanayo, i-ion ye-chloride iqukethe inani elithile lamandla okukhipha amanzi, okulula ukukhangiswa ezimbotsheni ezingaphezulu zensimbi kanye nemifantu futhi ithathe indawo yomoya-mpilo ongqimbeni lwe-oxide, ngaleyo ndlela iguqule i-insoluble oxide ibe yi-chloride encibilikayo kanye ne-passivated. beka indawo endaweni esebenzayo.

Usawotiisifutho sokuvikela ukugqwalatest isivivinyo semvelo esisebenzisa kakhulu izimo zemvelo zokufuthwa zikasawoti ezilingiswayo ezidalwe imishini yokuhlola isifutho sikasawoti ukuze kuhlolwe ukumelana nokugqwala kwemikhiqizo noma izinto zensimbi.Ihlukaniswe yaba izinhlobo ezimbili zokuhlola: ukuhlolwa kokuchayeka kwemvelo kwemvelo, kanye nokuhlolwa kwemvelo okusheshisiwe kokulingisa kwesifutho sikasawoti okusheshisiwe.

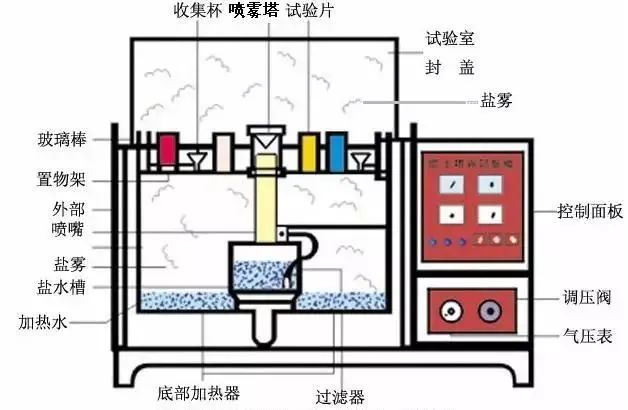

Ekuhlolweni kokwenziwa kwemvelo kokufuthwa kukasawoti okulingisa, kusetshenziswa igumbi lokuhlola isifutho sikasawoti elinenani elithile lendawo, futhi imvelo yesifutho sikasawoti ikhiqizwa kusetshenziswa izindlela zokwenziwa ngevolumu yayo yesikhala, ukuze kuhlolwe ukusebenza kanye nekhwalithi yokugqwala kwesifutho sikasawoti. ukumelana nemikhiqizo.

Ukugcwala kukasawoti kwe-chloride endaweni yesifutho sikasawoti kungaba izikhathi ezimbalwa noma izikhathi eziningi kunokuqukethwe kwesifutho sikasawoti endaweni evamile yemvelo, ngaleyo ndlela kwenyuse kakhulu izinga lokugqwala futhi kwehlise kakhulu isikhathi sokuthola imiphumela.Isibonelo, kungase kuthathe unyaka ukugqwala lapho kuhlolwa isampula lomkhiqizo endaweni engokwemvelo yokuchayeka, kuyilapho ungathola imiphumela yokuhlola efanayo ngemva nje kwamahora angu-24 endaweni yokwenziwa yokufafaza usawoti kasawoti.

Isifutho sikasawoti esilingisa elabhorethri singahlukaniswa izigaba ezine.

(1) Ukuhlolwa kwesifutho sikasawoti esingathathi hlangothi (ukuhlolwa kwe-NSS) kuyindlela yokuqala yokuhlola ukugqwala esheshisiwe futhi esetshenziswa kabanzi.Isebenzisa isixazululo samanzi anosawoti angu-5% we-sodium chloride, enenani le-pH elilungiselwe ububanzi obumaphakathi (6.5~7.2) njengesixazululo sesifutho.Izinga lokushisa lokuhlola lingu-35 ℃, futhi izinga elidingekayo le-sedimentation yesifutho sikasawoti ngu-1~2ml/80cm/h.

(2) Ukuhlolwa kwe-acetic acid salt spray (ukuhlolwa kwe-ASS) kwenziwa ngesisekelo sokuhlolwa kwesifutho sikasawoti esingathathi hlangothi.Kukusisombululo se-sodium chloride esingu-5% esine-glacial acetic acid, ukuze isixazululo esingu-PH sehliselwe cishe ku-3, isixazululo sibe ne-asidi, futhi isifutho sikasawoti esakhiwe ekugcineni siba ne-asidi esifuthweni sikasawoti esimaphakathi.Izinga lokugqwala kwalo lishesha izikhathi ezi-3 kunokuhlolwa kwe-NSS.

(3) Isivivinyo se-acetate spray test (ukuhlolwa kwe-CASS) usawoti wethusi osheshayo ukuhlolwa kokugqwala okusanda kuthuthukiswa.Izinga lokushisa lokuhlola lingu-50 ℃.Inani elincane le-copper salt-copper chloride lifakwa esixazululweni sikasawoti ukuze libangele ukugqwala.Izinga lokugqwala kwalo liphindwe izikhathi eziyisi-8 kunelokuhlolwa kwe-NSS.

(4) Ukuhlola isifutho sikasawoti esishintshashintshayo ukuhlola isifutho sikasawoti esibanzi, empeleni okuwukuhlolwa kwesifutho sikasawoti esimaphakathi kanye nomswakama oqhubekayo nokuhlola ukushisa.Isetshenziselwa ikakhulukazi umkhiqizo wohlobo lwe-cavity.Ngokungena kwendawo enyakazayo, ukugqwala kwesifutho sikasawoti kukhiqizwa hhayi kuphela ngaphandle kodwa nangaphakathi komkhiqizo.Umkhiqizo uguqulwa ngokushintshana phakathi kwesifutho sikasawoti kanye nomswakama kanye nendawo yokushisa, bese izici zikagesi nezemishini zomkhiqizo kufanele zihlolwe nganoma yiluphi ushintsho.

Ukunqunywa komphumela

Umphumela wokuhlolwa kokuhlolwa kwesifutho sikasawoti ngokuvamile unikezwa ngendlela yekhwalithi kunendlela yomthamo.Kunezindlela ezine eziqondile zokunquma.

(1) Indlela yokunquma izilinganiso.

Kule ndlela, hlukanisa isilinganiso sendawo yokugqwala kanye nendawo ephelele ibe amazinga amaningana, futhi unqume izinga elithile njengesisekelo esifanelekayo sokunquma.Le ndlela ilungele ukuhlolwa kwamasampuli ayisicaba.

(2) Indlela yokunquma yokukala.

Ngokukala isisindo sesampula ngaphambi nangemva kokuhlolwa kokugqwala, bala isisindo esilahlekile ngenxa yokugqwala, bese wahlulelafafaza ukuvikela ukugqwalaikhwalithi yesampula.Le ndlela ifaneleka ngokukhethekile ukuhlolwa kwekhwalithi ethile yokumelana nokugqwala kwensimbi.

(3) Indlela yokuhlaziya izibalo zedatha yokugqwala.

Le ndlela ihlinzeka ngezinga lokuzethemba lokuklama ukuhlola kokugqwala, ukuhlaziya idatha yokugqwala, kanye nokuthola idatha yokugqwala, esetshenziselwa kakhulu ukuhlaziya nezibalo zokugqwala, kunokuba ngokuqondile ukunqunywa kwekhwalithi yomkhiqizo.

Ukuhlolwa kwesifutho sikasawoti sensimbi engagqwali

Kusukela kwasungulwa ekuqaleni kwekhulu lamashumi amabili, ukuhlolwa kwesifutho sikasawoti kuye kwathandwa kakhulu ngabasebenzisi bezinto ezimelana nokugqwala ngenxa yezinzuzo zako ezihlanganisa isikhathi esincishisiwe nezindleko, ezikwazi ukuhlola izinto ezihlukahlukene, nokunikeza imiphumela elula necacile.

Empeleni, ukuhlolwa kwesifutho sikasawoti sensimbi engagqwali yikhona okwaziwayo kakhulu, futhi odokotela kumele bazi ukuthi mangaki amahora ukuhlolwa kwesifutho sikasawoti esingahlala kule nto.

Abathengisi bezinto ezibonakalayo bazovame ukunweba isikhathi sokuhlola isifutho sikasawoti sensimbi engagqwali ngezindlela ezinjengokudlula noma ukukhulisa izinga lokupholisha ngaphezulu.Kodwa-ke, into ebaluleke kakhulu enqumayo ukubunjwa kwensimbi engagqwali ngokwayo, okungukuthi okuqukethwe kwe-chromium, i-molybdenum ne-nickel.

Uma kuphakeme okuqukethwe kwakho kokubili i-chromium ne-molybdenum, kukhulu ukumelana nokugqwala okudingekayo ukuze kuqale ukubonakala.Lokhu kumelana nokugqwala kuvezwa yinani elibizwa nge-pitting resistance equivalent (PRE) value: PRE = %Cr + 3.3 x %Mo.

Nakuba i-nickel ingakukhulisi ukumelana kwensimbi nokugqwala kwe-pitting kanye nokugqwala, ingasebenza kahle ekwehliseni izinga lokugqwala uma inqubo yokugqwala isiqalile.Ngakho-ke, izinsimbi ezingenasici ze-austenitic eziqukethe i-nickel zivame ukwenza kangcono kakhulu ekuhlolweni kwesifutho sikasawoti kanye nokugqwala okungaphansi kakhulu kunezinsimbi ezingenasici ze-nickel ferritic ezinokulingana okufanayo kokumelana ne-pitting.

Kufanele kuqashelwe ukuthi usawotiisifutho sokuvikela ukugqwalaukuhlolwa kunezithiyo ezinkulu lapho kuhlolwa ukusebenza kwensimbi engagqwali.Okuqukethwe kwe-chloride yesifutho sikasawoti ekuhlolweni kwesifutho sikasawoti kuphezulu kakhulu futhi kuyidlula kude indawo yangempela, ngakho izinsimbi ezingenasici ezingamelana nokugqwala ezisetshenziswayo ezinokuqukethwe kwe-chloride ephansi kakhulu zizogqwala ekuhlolweni kwesifutho sikasawoti.

Ukuhlolwa kwesifutho sikasawoti kushintsha ukuziphatha kokugqwala kwensimbi engagqwali, okungabhekwa njengokuhlola okusheshisiwe noma ukuhlolwa kokulingisa.Imiphumela inohlangothi olulodwa futhi ayinabo ubudlelwano obulinganayo nokusebenza kwangempela kwensimbi engagqwali egcina isetshenziswa.

Ngakho ungasebenzisa ukuhlolwa kwesifutho sikasawoti ukuze uqhathanise ukumelana nokugqwala kwezinhlobo ezahlukene zensimbi engagqwali, kodwa lokhu kuhlola kukwazi kuphela ukulinganisa okokusebenza.Lapho ukhetha into ethile yensimbi engagqwali, ukuhlolwa kwesifutho sikasawoti kukodwa ngokuvamile akunikezeli ulwazi olwanele ngoba ukuxhumana phakathi kwezimo zokuhlola nendawo yohlelo lwangempela akuvamile ukwaziwa.

Ngaphezu kwalokho, izigaba ezahlukene zensimbi azikwazi ukuqhathaniswa nezinye, ngoba izinto ezimbili ezisetshenziswe ekuhlolweni zinezinqubo ezihlukene zokugqwala, ngakho imiphumela yokuhlolwa kanye nokufaneleka kokusetshenziswa kokugcina kwemvelo akufani.

Isikhathi sokuthumela: Jul-08-2022