Isingeniso

Lo mkhiqizo uwuketshezi olumhlophe oluyi-milky olutholwe ngokuphendula ama-silica nanoparticles angenalutho ngamaqembu asebenzayo anento ephilayo.Imbozwe phezu kwengilazi ngenqubo yokugqoka i-roller, futhi ngemva kokuphulukiswa kwezinga lokushisa eliphakathi kanye nokushisa okuphezulu kokushisa, indaba ephilayo ishiswe ngokuphelele, ama-nanoparticles azohlanganiswa ngokunembile futhi ancike esakhiweni esingenalutho se-silica nanoparticles khiqiza inkomba ephansi ye-refractive yesendlalelo sefilimu.

Amapharamitha

| Into | Amapharamitha ajwayelekile | Izimo Zokuhlola |

| Ukubukeka | 乳白色 ubisi olumhlophe | Ukuhlola Okubonwayo |

| Inani le-pH | 4±1 | pH Inkomba |

| Ukuminyana Okuhlobene (g/ml) | 0.82±0.05 | indlela ethile ye-gravity |

| Okuqukethwe okuqinile (%) | 3.0±0.4 | 120 ℃, amahora angu-2 |

| i-viscosity (cps) | 2.0±0.5 | 25℃ |

Izinkomba zokusebenza

Ukubukeka

uketshezi olumhlophe olubisi

Ukudlulisa

Ukuhanjiswa kukhuphuke ngaphezu kuka-2.3% ngesisekelo sengilazi emhlophe kakhulu, ngaphakathi kwebanga le-wavelength elibanzi elingu-400-1100nm (elikalwa kusetshenziswa uchungechunge lwedeskithophu entantayo yomoya ye-Beijing Taibo GST yabahloli bokudlulisa).

Ukuthembeka Inkomba

| Izinto | Izinqubo | Uhlaka Lwezithenjwa | Imiphumela | Amanothi |

| izinga lokushisa eliphezulu kanye nomswakama | Amahora angu-1000 | JC/T 2170-2013 | Ukunciphisa <1% | Ukuhambisana nezindinganiso zomkhakha |

| Ukuhlolwa kwesifutho sikasawoti | amahora angama-96 | JC/T 2170-2013 | Ukunciphisa <1% | Ukuhambisana nezindinganiso zomkhakha |

| Ukuhlola okuqanda okumanzi | 10 imijikelezo | JC/T 2170-2013 | Ukunciphisa <1% | Ukuhambisana nezindinganiso zomkhakha |

| Ukuhlolwa kokuhamba ngebhayisikili okushisayo | 200 imijikelezo | JC/T 2170-2013 | Ukunciphisa <1% | Ukuhambisana nezindinganiso zomkhakha |

| Ukuhlolwa kwe-UV | Iqoqwe ngu-15kw.h/m2 Isamba semisebe ngesikhathi | JC/T 2170-2013 | Ukunciphisa <0.8 | Ukuhambisana nezindinganiso zomkhakha |

| Ukuhlolwa Okusheshisiwe Kwe-PCT Ukuguga | Amahora angu-48 | JC/T 2170-2013 | Ukunciphisa <0.8 | Ukuhambisana nezindinganiso zomkhakha |

| Ukuqina kwepensela | ≥3H | JC/T 2170-2013 | Ayikho imihuzuko ebonakalayo | |

| Ukumelana ne-Acid | Amahora angu-24 | JC/T 2170-2013 | Ukunciphisa <0.8 | Ukuhambisana nezindinganiso zomkhakha |

| Ukuhlola Ukunamathela | Ukuhlolwa kwe-cross-cut | JC/T 2170-2013 | ibanga 0 | |

Izidingo Zenqubo

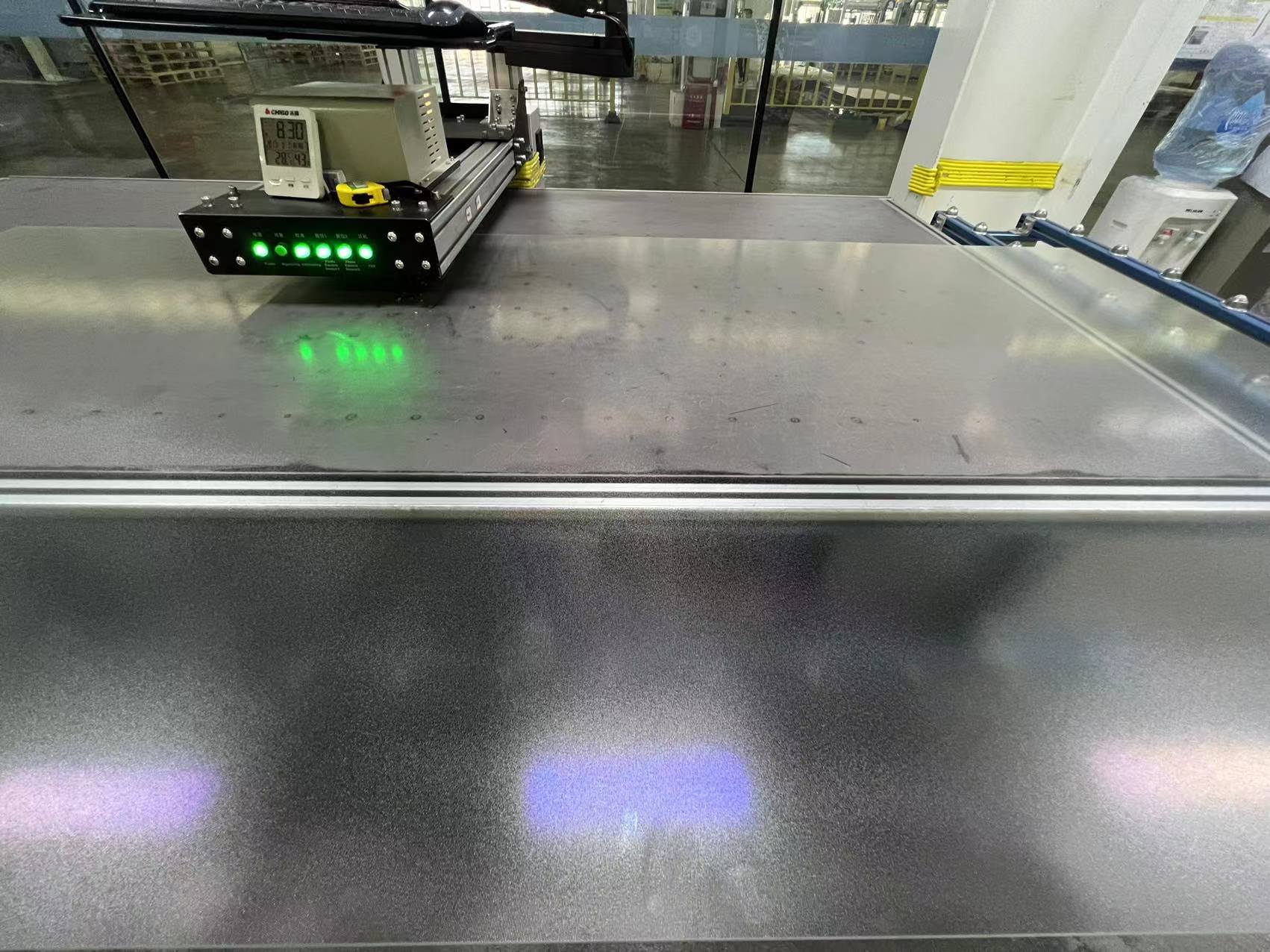

Isixazululo sokugqoka sisetshenziswa kusetshenziswa inqubo yokugqoka i-roll.

Ama-coating rollers kufanele asebenzise ama-PU rollers, ubulukhuni kufanele bube ngu-35 degrees -38 degrees kufanelekile, ukugqoka i-roller quantitative kunconywa ukusebenzisa i-80-100 mesh.

Ukushisa kwefilimu kungama-20-25 degrees.

I-coating ifilimu umswakama ≤ 45 degrees (high humidity board surface kulula ukungalingani).

I-Diluent: I-Isopropyl Alcohol (iphrinta yokuvala encane) noma i-ethanol e-anhydrous.

Izindlela zokuqeda ukuphrinta kwe-roller: i-raber roller lap indwangu engenalo uthuli noma indwangu ye-chamois.

Uma ifilimu yakhiwe, uma umswakama wegumbi lokumboza uphezulu kakhulu noma indawo yengilazi ingomiswanga emoyeni, indawo yefilimu izoba ne-athomu kalula ngemva kokwakhiwa kwefilimu futhi izinga lokudlulisa ukukhanya lizoncishiswa.

Izinyathelo zokuzivikela

Isixazululo sokumboza siyisistimu ye-nanosol esekwe ku-solvent (alcohol) futhi ayinabo ubuthi.Ngenxa yokuguquguquka okunamandla kwe-ethanol ye-anhydrous equkethwe kwisixazululo, amagilavu namamaski kufanele kugqokwe ngesikhathi sokusetshenziswa futhi umoya ohlanzekile ovamile kufanele usetshenziselwe ukugwema ukuthintana nokuphefumula noma ukuhogela ngokweqile okubangela isikhumba esomile nomphimbo kanye nokungakhululeki kwamehlo.

umkhiqizo kufanele ugcinwe ku-25 degrees centigrade ngezansi, ungagcinwa izinyanga ezingu-3, inqubo yokugcina kufanele igwenywe ukuthintana nomlilo kanye nomthombo oqinile wokukhanya kwelanga eliqondile, ukuze ungabangeli ukuguga komlilo noma ukushisa.