Kuthunyelwe ku 2019-01-11Izimo ezintathu zebhizinisi, ukulawulwa okukodwa kanye nokubili okuhlobene nokusebenza abakhiqizi abahambisa izinto zokubopha, iziqeshana kanye nezitembu ezincane ezihlobene ukuze bacabangele ukusetshenziswa kobuchwepheshe bokuhlanganisa i-dip spin.

Okokuqala, abalawuli bezemvelo bayaqhubeka nokugxila ekufakeni.Okwesibili, inombolo nevolumu yezinhlelo zokusebenza ezidinga ukusebenza okuphezulu kwe-coating ngokuya ngesifutho sikasawoti, isilinganiso se-Kesternich kanye nokungezwani kwe-torque okungaguquki kuyanda.Ukusebenzisa i-dip spin coating phezu kwepuleti elincane le-zinc ukuze kuhlanganiswe i-zinc kuyimpendulo esebenzayo futhi eyongayo.Imiphumela yokuhlolwa kwesifutho sikasawoti ingakhuliswa ukusuka emahoreni ayi-120 kuye kwayi-1,000 kusetshenziswa le ndlela.Kuyathandeka futhi kwezinye izindlela eziningi ngokombono wemvelo.Okokugcina, i-hydrogen embrittlement iyinkinga eqhubekayo, futhi i-dip/spin ibonise ikhono lokunciphisa noma lokuqeda kakhulu le nkinga.

I-Dip spin inqubo lapho umkhiqizo ufakwa kubhasikidi onenetha, ucwiliswe kusisombululo sokumboza bese uphothwa ukuze kukhishwe ukunamathela okweqile.Izinga lokushisa kanye ne-viscosity ye-coating, isikhathi sokucwiliswa, isiqondiso sokujikeleza kanye nesivinini kanye nendlela yokwelapha kuphakathi kokuguquguqukayo okuvumela abasebenzisi ukwenza ngendlela oyifisayo iresiphi yenqubo futhi bathole imiphumela enembile, ephindaphindwayo kakhulu.

Okunye okuphawulekayo yikhono le-dip/spin lokunciphisa izindleko zakho kokubili okokuhlanganisa nokulahlwa kukadoti.Lokhu kungenxa yobuchwepheshe obungama-98 pct noma ngaphezulu ekusebenzeni kahle kokudlulisa okumaphakathi.

Amasistimu we-Dip spin afana nalawo akhiqizwa i-Spring Tools, i-Portage, i-Michigan, anenzuzo kakhulu ezingxenyeni ezincane ezinamakhonsathi athile kanye nalezo ezingambozwa ngobuningi ngaphandle kokunamathelana.Futhi nakuba kukhona okuhlukile okuphawulekayo (umkhiqizi we-fastener oyedwa ulungisa amabhawodi akhe amakhulu kakhulu ukuze kucutshungulwe i-dip/spin), ukusebenza kahle kwenqubo kwenziwa ngezingxenye ezingamayintshi angu-10 noma ngaphansi ubude nama-intshi angaphansi kwamabili ngobubanzi.

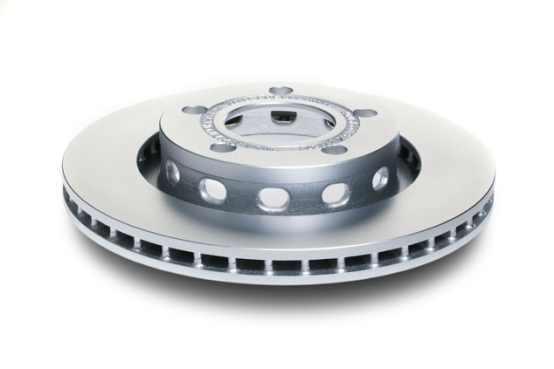

Ngenkathi amawasha nezinye izinto eziyisicaba ziboshwe ngokuphumelelayo nezinye izindlela, idiphu/i-spin ifaneleka kahle ukufulela nezinye izinsimbi zokwakha, izinsimbi, iziphethu, ama-o-ring, ama-u-bolt, izipikili nezikulufu, izikhwebu zezimoto nezinye izinto eziningi ezisetshenziswayo. ukuze kuqedelwe ngomshini.

Ubuchwepheshe be-Dip spin buhambisana nazo zonke izinhlobo zokumboza ezinkulu ezisetshenziswa ekuqedeni i-fastener;ngokukhethekile, izimbotshana ezihlanganisa ukumelana okuphezulu nokugqwala kwamakhemikhali kanye ne-galvanic/bi-metallic ngokuzinza kwe-UV, izakhiwo zokulwa ne-galling kanye/noma izici zokulwa nokudlidliza.Iningi lizophinde lihambisane nama-sealant, izinto zokunamathisela kanye neziqephu zokukhiya futhi zizokoma lapho zelashwa lapho zelashiwe.Izinhlobo ezithile zokumboza ezihilelekile zifaka ama-fluorocarbon, anothe nge-zinc, i-ceramic metallics (i-aluminium-based with organic or inorganic topcoat) kanye namasistimu ahamba emanzini.

Inqubo ye-dip spin ihlanganisa izinyathelo ezintathu: 1) Ukuhlanza nokwelashwa kusengaphambili;2) Coatings isicelo;kanye 3) Ukwelapha.Abakhiqizi bezinsimbi ngokuvamile basebenzisa igrit ye-aluminium oxide engu-80- kuya ku-100-mesh ukuze basuse ama-oxide nezikali zokwelapha ukushisa.I-Micro-, medium- or heavy-crystalline zinc phosphate iwukwelashwa kwangaphambili okuthandwayo lapho kudingeka khona, nakuba kukhona ama-dip/ spin coatings ambalwa angasetshenziswa phezu kwensimbi engenalutho.

Ngemuva kokoma, izingxenye zilayishwa kubhasikidi olayini we-wire-mesh.Uma ukulayisha kuzenzakalela, isistimu idlulisela izingxenye ku-hopper yesikali esinezisindo zeqoqwana esethwe ngaphambilini.Ngemva kokulayisha, izingxenye zidluliselwa egunjini lokucwilisa/le-spin futhi ku-spin yesikhulumi esizungezayo lapho zivalwa khona.Isitsha sokumboza, esibekwe ngqo ngezansi, siyaphakanyiswa ukuze sicwilise ubhasikidi wezingxenye ekuhlanganiseni.

Lapho isikhathi sokucwiliswa sesiphelile, isitsha sokumboza siyehla sifike endaweni lapho ubhasikidi usesesitsheni, kodwa ngaphezu kwezinga eliwuketshezi.Ubhasikidi ube usu-centrifuged.

Umjikelezo we-spin ojwayelekile uzoba indlela eyodwa yamasekhondi angama-20 kuye kwangama-30, ibhuleki eligcwele, bese ihlehla i-spin isikhathi esilinganayo.Isenzo sokubhuleka siqondisa kabusha izingxenye ukuze zisuse ngokuphumelelayo ama-coatings ezinsikeni.Uma i-dip/spin isiqediwe, umkhumbi wokumboza wehliswa ngokugcwele futhi ubhasikidi uhlelwa kabusha, uyavulwa futhi ususwe.Ukulayisha kabusha kwenzeka futhi inqubo iyaphindwa.

Izinto zokugqoka zifakwa emkhunjini wensimbi futhi zifakwe futhi zikhishwe ngomnyango wokungena ohlangothini.Ukushintsha umbala kufezwa emizuzwini eyi-10 kuye kwengama-15 ngokukhipha isitsha sokuqala sokumboza nobhasikidi bese ufaka okusha.Izembatho zigcinwa esitsheni sokucwilisa/sospini, esivalwa ngesivalo sensimbi noma se-polyethylene.Obhasikidi abanemeshi bahlanzwa kusetshenziswa i-solvent soak noma i-grit blast noma i-mesh liner iyodwa icutshungulwa kuhhavini oshile.

Izembatho ezimbalwa ezisetshenziswa ku-fastener eqeda ukomisa umoya.Ku-90 pct plus edinga ukushisa, imigqa emincane yediphu/spin ihlanganisa i-batch oven;imishini emikhulu ihlanganisa i-oven yebhande elihanjiswayo.Amabhande okuthutha alinganiswa ezingxenyeni.Izingxenye ezimboziwe zilayishwa ngqo ebhandeni lehhavini futhi zisakazwa ngesandla phezu kobubanzi.Noma, alayishwa kuthreyi yokudlidliza ebeka izingxenye phezu kwebhande likahhavini ngokuzenzakalelayo.

Imijikelezo yokwelapha isukela kumaminithi amahlanu kuya kwangu-30;izinga lokushisa eliphezulu lensimbi liyi-149 kuya ku-316F.Isiteshi sokupholisa komoya ophoqelelwe sibuyisela izinga lokushisa lomkhiqizo eduze ne-ambient.

Imishini ye-Dip spin ikhiqizwa ngosayizi abalinganisiwe ukuze kucutshungulwe izidingo.Lapho amaqoqo omkhiqizo emancane futhi kudingeka izinguquko eziningi zemibala, isistimu encane, enobhasikidi obubanzi obuyi-intshi engu-10, umthamo ongu-750 lb/hr kanye nesivinini sokujikeleza ukusuka ku-zero ukuya ku-900 rpm kunganconywa.Lolu hlobo lwesistimu luzokwamukela ukusebenza okwenziwa ngesandla, lapho u-opharetha elayisha ubhasikidi futhi asebenzise izingxenye ze-dip and spin zemijikelezo esebenzisa amavalvu esandla noma i-automation ingxenye lapho ukulayisha/ukukhipha kwenziwa ngesandla, kodwa imijikelezo ilawulwa yi-PLC.

Umshini ophakathi nendawo, ofanele izitolo eziningi zemisebenzi usebenzisa ubhasikidi ongu-16 amayintshi ububanzi nomthamo osebenzisekayo we-cu ft eyodwa. Umthamo ungalinganiselwa ku-150 lbs.Lolu hlelo ngokuvamile luzocubungula umkhiqizo ofika ku-4,000 lbs/hr kanye nesivinini sokujikeleza esingafika ku-450 rpm.

Abakhiqizi abakhulu bezinto zokubopha nezitolo eziqeda umsebenzi ngokuvamile bahlinzekwa kangcono ngesistimu esebenzisa ubhasikidi ongu-24-intshi ububanzi futhi enesivinini sokujikeleza esingafika ku-400 rpm.

Isikhathi sokuthumela: Jan-13-2022