Inani elincane le-oda:500 Kilogram

Imininingwane yokupakisha:1000kg/umgqomo

Isikhathi sokuthumela:Ezinsukwini eziyishumi ngemuva kokuthola inkokhelo kusengaphambili

Ikhono Lokuhlinzeka:Amathani ama-2 ngosuku

Umbala:Uketshezi Olungenambala Kuya Kuphuzi

Isisindo Esithile:1.00-1.10

PH:13.0-14.0

I-Alkalinity yamahhala (i-piont):≥20

Ukupakisha:1000kg/umgqomo

Isikhathi sokuqinisekisa:Unyaka owodwa

Incazelo

1. kafushane

Imikhiqizo ye-Junhe Type-1017 iyimikhiqizo enengxenye eyodwa ehlanganiswe ikakhulukazi nosawoti we-potassium, i-corrosion inhibitor, inkimbinkimbi, okokuhlanza kanye ne-surfactant nge-polymerization.I-reagent grade potassium hydroxide inikeza i-saponification alkalinity.I-polymerization corrosion inhibitor, inkimbinkimbi, okokuhlanza kanye ne-surfactant ihlinzeka ngokuhlanza.Lo mkhiqizo usebenza kahle kakhulu emulsifying, saponification kanye nokuhlanza uwoyela wezilwane, uwoyela wemifino, uwoyela wamaminerali, ukumiswa nokunamathisela kokugaya.Inomphumela oqinile wokuhlubula, oyinkimbinkimbi nokuhlanza kuma-ion ensimbi.Ukuhlanzwa kwamafutha kungu-99% njengokutholwa.Ukuhlubula, ukuxaka nokuhlanza umphumela wethusi, insimbi namanye ama-ion ensimbi.Ngaleso sikhathi, imikhiqizo ye-Junhe Type-1017 ayinayo i-phosphate, i-calcium, i-magnesium, insimbi, ithusi, i-lead namanye ama-ion ensimbi e-silicon ayingozi futhi ihlangabezana nezidingo ze-EU ROHS ngokuvikelwa kwemvelo okuhle nekhono eliqinile lokuhlanza.

2. isici

I-1) Imikhiqizo ye-Junhe Type-1017 iyimikhiqizo yengxenye eyodwa yokuhlushwa ephezulu engangezwa ngokuqhubekayo nepompo ezenzakalelayo kulayini othomathikhi.

2) Ayiqukethe i-phosphorus futhi ihlangabezana nezidingo zokuvikela imvelo ze-EU ROHS.

3) Kuwuhlobo lomkhiqizo ophansi wegwebu futhi ungasetshenziswa kulayini wokufafaza kanye ne-ultrasonic ngaphandle kwegwebu elichichimayo.

I-4) Okuqukethwe kwe-ion yensimbi akudluli i-50PPm ngaphandle kwe-potassium ne-sodium ion futhi ingahlangabezana nemfuneko ye-IT yokunemba okuphezulu.

5) ukusebenza okuhle kokwehlisa ukuze kuhlangatshezwane nesidingo sendawo ye-IT enembayo.

3. sebenzisa imiyalelo

1) engeza amanzi ahlanzekile angu-3/4 ethangini lokuhlanza kuqala.

2) uma uyisebenzisa kulayini owenziwe ngesandla, kuphakanyiswa ukuthi wengeze u-5 ~ 10 kg we-Junhe Type-1016 i-silicon yokuhlanza i-ejenti yokuhlanza i-silicon ku-1000 litre fluid fluid.Lapho uhlanza i-silicone chip yokupholisha nokugaya inamathisele ne-silicon chip enqunywe ngokumiswa kokululama, kufanele wengeze imithamo eyengeziwe phakathi namahora angu-8 okushintsha ngokuvumelana nencazelo yenkampani ngayinye.Vele, yehlisa imithamo lapho ugcina isivuno se-silicon chip.

3) Uma wengeza ngokuqhubekayo emugqeni ozenzakalelayo, vula ithangi nge-ejenti yokuhlanza i-silicon chip engu-1 ~ 2 kg ye-1017 ngoketshezi lwethangi lamalitha ayi-100 futhi ulawule ukungeza okuqhubekayo ngokwenani lokuhlanza i-silicon chip yomugqa othomathikhi.Ukuze uthole umphumela ongcono wokuhlanza, kuphakanyiswa ukuthi ushintshe amashifu angu-1 ~ 3 ngamunye.

4) Ngokuvamile ikhilogremu ngayinye ye-Junhe Type-1017 silicon chip cleaning agent ingahlanza ama-silicon chips angaphezu kuka-1000 angu-125# monocrystal silicon chips.Engeza ngokwale ngxenye.Lapho uhlanza ukupholisha nokugaya unamathisela i-silicon chip ne-silicon chip cut ngokumiswa kokululama, kufanele wengeze imithamo eyengeziwe.Vele, yehlisa imithamo lapho ugcina isivuno se-silicon chip.

5) Bese wengeza amanzi ahlanzekile kuze kufike izinga lokusebenza nokushisa ekushiseni okudingekayo bese ungawasebenzisa.

6) I-silicon chip kufanele ivezwe ngokungavamile ngangokunokwenzeka ngesikhathi sokuhlanza ukuze kuvinjwe ukukhiqizwa kwezingxenye zezimbali.

4. amanothi

1) Induku yekristalu ayikwazi ukuba manzi ngemuva kokusikwa ngomugqa.Uma ingakwazi ukuhlanzwa ngesikhathi, kuzoba ngcono ukuthi ifakwe ku-ejenti yokumiswa noma yokuhlanza (icwiliswe ngokugcwele)

2) Uma induku yekristalu ngemuva kokusikwa komugqa isihlanziwe, kufanele kubhekwane nayo ngokushesha.Akuvunyelwe ukwenza i-silicon chip yome ngokwemvelo ngesikhathi sokuhlanza.

I-3) Kumele igcine i-silicon chip imanzi uma i-degumming futhi akufanele iyenze yome ngokwemvelo.

4) Vala inkinobho enegwebu lapho uhlanza ithangi 1 no-2 nge-ultrasonic ngemva kokuba emashalofini, vula okugcwele amagwebu futhi ugweme ikakhulukazi ukukhiqizwa kocezu.

5) ngemva kokuqedwa komjikelezo wokuhlanza ngamunye (njengokushintshashintsha), shintsha amathangi ahlanzekile ethangi 5, ithangi 6, ithangi 7 kanye nethangi lesi-8 kahle.

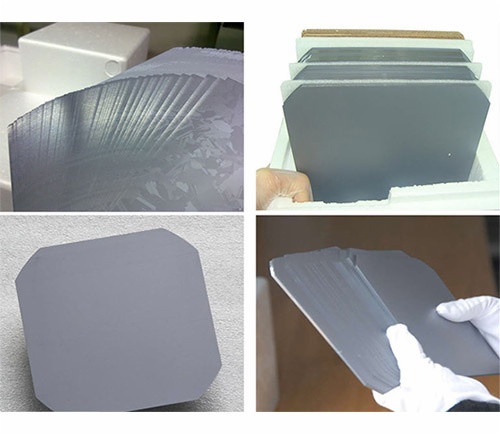

6) Izisebenzi zokuhlanza azikwazi ukuthinta i-silicon chip ngesikhathi sokuhlanza futhi kufanele zigqoke amagilavu enjoloba uma kwenzeka kuphrintwa iminwe.

7) Ukuze ugcine ukuhlanzeka kwe-silicon chip, isikhathi sokuhlanza sokufafaza ngaphambi kokukhishwa kwe-degumming kufanele silawulwe kungakapheli imizuzu engama-30.

8) Uma kunezinkinga ezifana ne-chip engcolile kanye nomlilo ngesikhathi sokusebenzisa, sicela uxhumane nabasebenzi besevisi yezobuchwepheshe ngesikhathi.

9) Lapho ukhipha umkhiqizo, udinga ukungathathi hlangothi, ukugeleza kwe-flocculation kanye ne-sedimentation nokunye ukucubungula okulula.Umkhiqizo awunayo insimbi enzima ne-orthophosphate.

Idatha Yezobuchwepheshe

| Ukubukeka | Uketshezi olungenambala ukuya kokuphuzi |

| Isisindo esiqondile | 1.00-1.10 |

| PH | 13.0-14.0 |

| I-alkalinity yamahhala (piont) | ≥20mg |