Inani elincane le-oda:100 Kilogram

Imininingwane yokupakisha:

Iphakethe A: 16kg / Metal Barel

Iphakethe B:24KG Plastic Barel

Iphakethe C:Kusekelwe enanini le-ejenti engu-B

Isikhathi sokuthumela:Ezinsukwini eziyishumi ngemuva kokuthola inkokhelo kusengaphambili

Ikhono Lokuhlinzeka:Amathani ama-2 ngosuku

Indlela Yokumboza:Dip Spin & Spray

Umbala:Isiliva

PH:3.8-5.2

I-Gravity ethize:1.33±0.05( Ukufutha)1.33±0.05(I-dip-spin Coating)

I-Viscosity:Ngokusho kwe-Operating Demand.

Izinga Lokushisa Lokusebenza:20±2℃

Incazelo

I-JH-9382 yakhiwe ngamaphakethe amathathu: A,B no-C;

Iphakethe A: I-silver grey slurry ehlanganiswe amakhemikhali ikakhulukazi ne-super fine flake Zn, i-super flake Al kanye nesengezo se-organic.

Iphakethe B: Isixazululo samanzi esihlanganiswe ikakhulukazi nesithako se-corrosion protecion, isisombululo samanzi esilawulayo esithile njll.

I-Pack C: I-tackifier ye-coating eyenziwe ikakhulukazi nge-cellulose emhlophe noma impushana ephuzi.

Izici zokusebenza:

Ifilimu imhlophe ngesiliva, isiphetho esihle, ukumelana nokugqwala okuphezulu, ukunamathela okuhle.

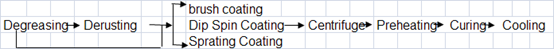

Inqubo yokumboza

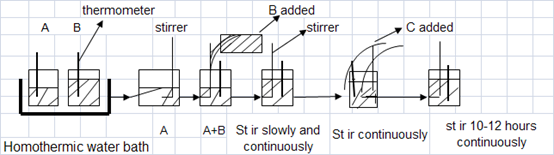

1. Mix Isilinganiso

Iphakethe A: 16.0 kg

Iphakethe B:24.0 kg (inani linganyuswa ngokufanele uma isifutho sifakwa)

Iphakethe C:0-50 g (ngokwesidingo esihlukile se-viscosity)

2. Ngaphambi Kwengxube, Gcina i-A&B enesisindo kubhavu wamanzi ongu-25±2℃, bese ugoqa u-A ukuze wenze udaka lwensimbi luhlakazeke ngokufanayo nge-frequency mixer, ngemva kokuthi u-A ehlakazwe ngokulinganayo ngokugcwele, yehlisa ijubane elinyakazayo libe ku-60r/min, bese wengeza u-B. .

Engeza u-B ekunyakazeni u-A kancane kancane.Okwamanje, izinga lokushisa lomgqomo lizokhuphuka, lapho lifinyelela ku-35 ℃, qalisa idivayisi yesiqandisi ukugcina izinga lokushisa lomgqomo lingaguquki ku-35 ℃.

3.Faka u-B ekunyakazeni u-A kancane.Okwamanje, izinga lokushisa lomgqomo lizokhuphuka, lapho lifinyelela ku-35 ℃, ukuqalisa idivayisi yesiqandisi ukugcina izinga lokushisa lomgqomo lingashintshi ku-35 ℃.

4. Hlanganisa ingxube cishe amahora angu-1 ~ 2 ngokushesha ngemva kokuba u-B esengeziwe, bese ufaka u-C. C kufanele ube yimpushana uma kukhona isigaxa.(Izinga lokushisa lomphongolo akufanele libe ngaphansi kuka-30℃, ngaphandle kwalokho u-C ngeke uncibilike ngokwanele). Amahora angu-12 ngokuqhubekayo.

5. Ukugqoka kufanele kuhlungwe ngesikrini sensimbi engagqwali eyi-100 ngaphambi kokuthululelwa emgqonyeni wokucwilisa.

6. Idivayisi yokulawula izinga lokushisa kufanele ifakwe umgqomo wokucwilisa ukuze kugcinwe izinga lokushisa lokumboza liku-22±2℃.

(Uma izinga lokushisa liphezulu kakhulu, upende ungawohloka, futhi i-viscosity izokwenziwa.) Ukugqoka kufanele kunyakaziswe ngokuyindilinga ukuze kuhlale kuhlakazeke ngokulinganayo.

7. Ukuminyana kokuhlolwa, PH, izinga lokushisa, i-Viscosity kanye nokuqukethwe kwe-Cr6+ kokunamathela njalo emahoreni angu-8 uma kusebenza ngokuqhubekayo.

Hlanganisa umdwebo

Ukunakwa

Amanye amakhemikhali anjenganoma iziphi izinhlobo ze-asidi, usawoti we-alkali awukwazi ukuxutshwa enamathela, ngoba lawa angenza i-Zn & Al plate isebenze ukuze iguge.

Gwema imisebe yelanga nemisebe ye-ultraviolet isikhathi eside uma isebenza, ngaphandle kwalokho izosheshisa ukuguga noma ukwenziwa kwe-polymerization kokunamathela.

Kubaluleke kakhulu ukulawula izinga lokushisa lokugqoka.Uma izinga lokushisa lokugqoka lishintsha lapho usebenza, lizokwenza i-viscosity, bese i-effect quatity yokugqoka ku-workpiece.Ngakho-ke ubudlelwano phakathi kwezinga lokushisa, i-viscosity kanye nenqubo yokuphotha kufanele ilawulwe kahle lapho unamathela.

I-viscosity izohluka uma indlela yokugqoka ihlukile.Khetha idatha ephansi uma i-spray coating, bese ukhetha idatha ephezulu uma i-dip spin coating.

Idatha Yezobuchwepheshe

| Cha. | Into | Idatha |

| 1 | Umbala | Isiliva |

| 2 | Indlela yokumboza | Dip Spin & Spraying |

| 3 | PH | 3.8-5.2 |

| 4 | I-Cr6+ | ≥25g/L |

| 5 | Amandla adonsela phansi athize | 1.33±0.05( ukufutha)1.33±0.05(i-dip-spin coating) |

| 6 | I-Viscosity | Ngokusho kwesidingo sokusebenza. |

| 7 | Izinga lokushisa lokusebenza | 20±2℃ |